Business News – Update of the Pot Tending Machine (PTM) simulator –

The aluminium market in a nutshell

Aluminium is one of the most precious metals of our time, used in a variety of applications ranging from aerospace to the automotive industry. Its lightness, strength and malleability make it an essential material. However, producing aluminium is no mean feat, and the operators who oversee the electrolysis processes play a crucial role in the manufacture of this precious metal.

The aluminium market is constantly evolving, forcing the industry to stay at the forefront of technology and constantly look for ways to improve efficiency and train operators. That’s where our scope comes in: updating the Machine Service Electrolysis driving simulator. This technological innovation promises to redefine operator training in the aluminium industry.

Focus on the Pot Tending Machine process

Operating Pot Tending Machine is a complex task, requiring an in-depth understanding of how the process works. Operators need to monitor a range of parameters in real time to ensure the production of high-quality aluminium. An error can lead to costly disruptions and production stoppages.

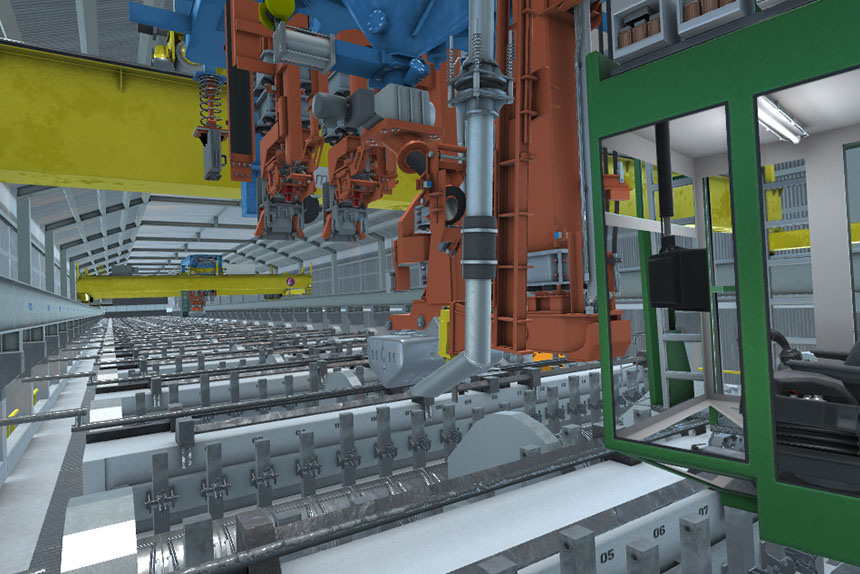

The Pot Tending Machine driving simulator has been designed to allow driving operators to train in a virtual environment, simulating all the variables and real plant conditions. This virtual training offers a safe and effective way to gain experience and improve the skills needed to operate the machine. With personalised training scenarios and instant feedback, operators can prepare for any situation, reducing the risk of errors in real-life situations.

Our scope

Updating the Pot Tending Machine simulator is a major step towards improving operator training in the aluminium industry. Our engineers have incorporated the latest technological advances, real-time plant data and operator feedback to create an even more realistic and effective simulator.

The main features of our update include:

– Improved graphics rendering for a better user experience, including more precise objects and better overall lighting.

– Addition of a VR option: virtual reality for even greater immersion

Assessment

Operators can view the process either on a screen or via the VR headset. These modifications provide an even more faithful reflection of the real-life conditions of MSE machines. Our simulator ensures better preparation of operators, thus reducing training costs and time.

Acknowledgements

We would like to thank our loyal customer Fives for renewing its confidence in us with this simulator update.