IESA supports you in the digitalisation of your training courses

IESA has been integrating new digital technologies for over 15 years. Listening to the needs of their clients, the IESA experts developped a digital training tool.

Coming from the industry world, and having a real expertise in « Virtual Reality » technologies, IESA is the perfet partner to help the industrials in the digitalisation of their training.

This digitalization represents a major challenge which benefits are no longer to be proven:

- No machine hogging

- Environment control

- Training delivered at lower cost

- A fun tool that promotes rapid learning (serious game)

Thanks to our experience, we are able to offer the best technical solution for example through the use of immersive headsets or 3D projection technologies. We adapt and propose tailor-made solutions, that meet the specific needs of each training project.

One of a real advantage is to allow everyone to familiarise with the operation of the installations and their management in a virtual way. That popularises access to real machines and increases the efficiency of operators. Indeed, some of them can be very impressive for newcomers.

To develop digital twin of installation, we use technologies coming from the video games industry. Thus, we realistically design the process environment by integrating the physical behaviours of the machine. We can also include the connexion from the process to its control-command (PLC, Supervision…)

We have lots of sucessful implementations in very different markets. Here are some examples :

Our immersive training simulator, which provides much more realisme than others, is used to train operators working on the process of segment erectors. This is the critical path in the tunnel construction process !

The installation of our simulator was done on site in order to save time and ensure the availability of the tool. It differs from the generic solutions found usually because its a real twin of the machine which uses the 3D models, the physical control interfaces as well as the PLC programs.

It is used today to train the operators on the H2S (High Speed 2) site in England.

The particularities of this site :

- It is essential for the Bouygues Travaux Publics consortium to have trained and efficient operators,

- The work site has an important safety aspect, particularly concerning people,

- It also involves a financial issue: ring laying is the critical path of production. So, it cadences the various activities necessary for the operation of the TBM,

- Quality of the segment installation is very important, the performance of the tunnel depends on it.

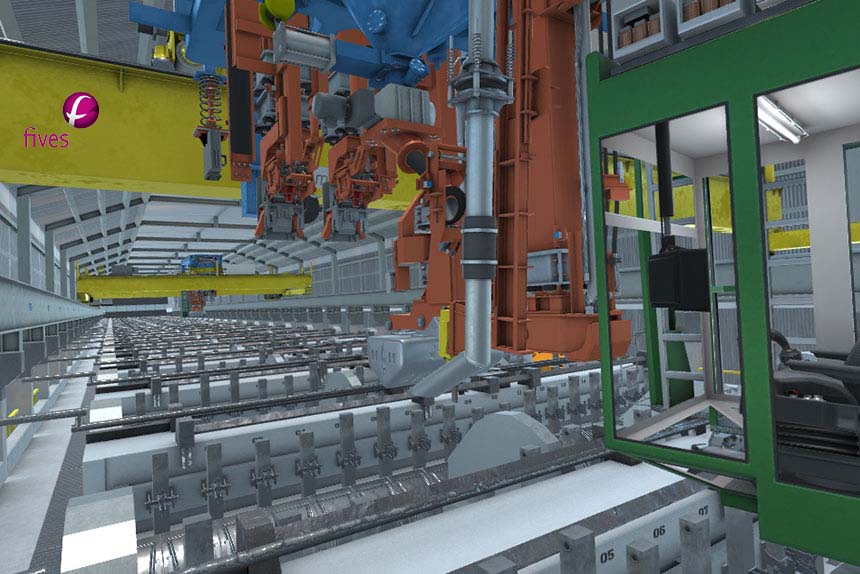

Our training simulator is used in the aluminium plant to train the operators on the anode replacement process and electrolytic cell maintenance.

The proposed and adopted solution requires a dedicated space! The solutions are numerous: creation of a specific room or a container fitted out according to the projects with reproduction of the cabin, installation of large screens and video projectors for an optimal immersion.

Thanks to its sucess, this tool is used in a dozen of alumium plants around the world : Middle East, Iceland, Canada, India, Australia, South Africa, Mozambique etc…

Features of this product:

- Precision in terms of expected results,

- Creation of different exercises with increasing difficulty,

- Implementation of a real educational curriculum,

- Recording of datas,

- Analysis of the operator’s behavior on the machine

- Issuance of a driving license,

Our training simulator has been developed to train driving and maintenance operators to the different scenarios of failure and emergency on a Ski Lift installation.

This tool allows drivers to interact on all lines and to learn how to identify and transcribe faults. To reduce the time of implementation, the scenarios are directly integrated in the simulator.

Features of this product:

- The operator can take control of the tool and create his own scenario

- The application allows to replay a technical incident

- Operators are alerted to eco-driving by learning how to limit their energy consumption

- The solution allows to train both driving and maintenance operators

Our training simulator is used to train newcomers to the access of nuclear controlled areas. These access is highly regulated and the security aspect is important.

Equipped with an immersive helmet, the learner is put in a real situation and must perform a set of tasks according to a previously defined scenario. He must comply with the rules of access to the site, and has to have the right reactions when he faced with unforeseen events. This interactive approach allows a better understanding and memorization of the safety requirements and obligations of the nuclear sector.

Features of this product:

- Our immersive solution makes it possible to deliver the training regardless the site

- We have developed the tool by integrating fun and educational scenarios

- The simulator completes the global training of newcomers

You have a project in mind? Need more information, don’t hesitate to contact us at 04 74 16 00 01 or by mail at contact@iesa-group.com !