IESA’s industrial electrical expertise sought by contractors, a new business in the waste-to-energy market

What do we mean by electrical work?

In the industrial world, electrical work encompasses a wide range of activities crucial to ensuring the smooth running of installations.

1/ Electrical audits and site surveys

Industrial electrical services include audits and site surveys, which assess the current state of electrical installations and identify any maintenance, repair, upgrading or replacement requirements.

2/ Design and electrical diagrams

Next comes the design and schematic phase, during which electrical engineers draw up detailed plans for new electrical systems or modifications to existing ones. Installation studies are also essential, as they enable us to analyze the technical and logistical constraints involved in installing electrical equipment.

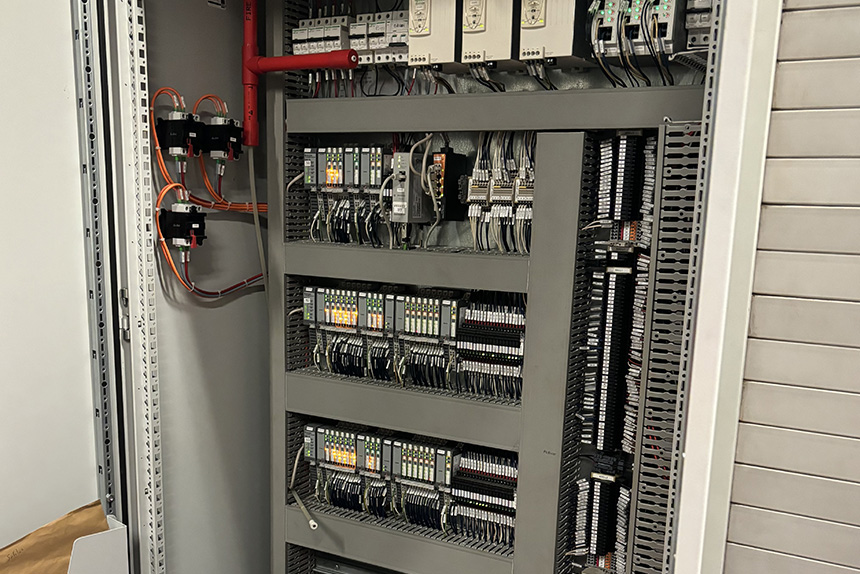

3/ Electrical equipment manufacturing

Once the plans have been drawn up, it may be necessary to manufacture the electrical equipment, whether in the form of boxes or electrical cabinets of any size… This equipment often requires the routing and pulling of power and control cables. At the same time, managing the electrical works contract involves selecting and coordinating subcontractors and suppliers to ensure that the work is carried out to the agreed standards and timescales.

4/ Electrical site supervision

Finally, electrical site supervision is a crucial step in ensuring the quality and safety of electrical work in the field. Supervisors ensure that plans are properly implemented, safety standards are met, and any problems are quickly resolved to minimize delays and risks to workers and installations.

What are the challenges of electrical work in a waste-to-energy plant?

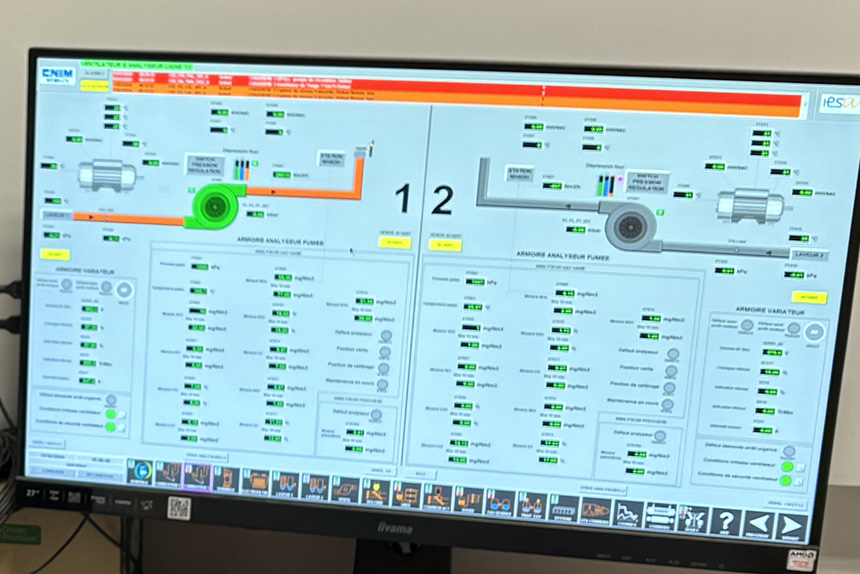

1/ Reliable electrical installations

Waste-to-energy plants require reliable electrical installations to guarantee safe operation. Any malfunction can lead to breakdowns and even fire hazards.

2/ Efficient electrical installations

Efficient electrical equipment is essential to maintain continuous, optimum production in a waste-to-energy plant. Any stoppage in production can result in substantial financial losses.

3/ Electrical equipment subject to strict standards and regulations

Waste-to-energy plants must comply with strict electrical safety standards to ensure regulatory compliance and avoid potential fines.

4/ Optimized electrical energy management minimizes ecological impact

Efficient electrical energy management is crucial to reducing operating costs and minimizing the ecological footprint of a waste-to-energy plant.

To see our achievements in the UVE market, click here.

An expert industrial electrician: real added value for site supervision

1/ Industrial electricity: real expertise

An expert industrial electrician has in-depth knowledge of industrial electrical systems, enabling him or her to effectively supervise the installation and maintenance of electrical equipment at a waste-to-energy plant.

2/ Industrial electricians know how to manage risks

Industrial electricians can identify and mitigate the risks associated with electrical work, helping to ensure the safety of workers and installations.

3/ Industrial electrical expertise to optimize performance

By monitoring and optimizing the performance of electrical equipment, the expert can help maximize plant operational efficiency and reduce unplanned downtime.

4/ The industrial electrical expert masters regulatory compliance

The industrial electrical expert is familiar with electrical safety standards and regulations, ensuring that all work is carried out in compliance with legal requirements.

IESA's industrial electrical experts called in by a waste recovery plant

1/ IESA’s electrical expertise recognized by the S.M.A.

It was against this backdrop that our client Société Monégasque d’Assainissement (S.M.A) called on us for its waste-to-energy plant in Monaco. As part of a new contract, our industrial electrical experts will be carrying out a number of electrical works at the plant.

2/ Obsolete electrical equipment requiring a complete electrical scope

Our industrial electrical experts will update some of the obsolete electrical equipment. They will carry out the following electrical scope

– Dismantling aging equipment,

– Modifications required to integrate new devices into electrical cabinets,

– Installation of the new cabinets and their connections in the locations defined by the studies,

– Electrical supervision of the worksite by an expert in industrial electricity, to optimize its efficiency and success.

Electrical work at the Monaco waste-to-energy plant: a big thank-you to its managers

We would like to express our gratitude to our loyal and long-standing customer Société Monégasque d’Assainissement (S.M.A) for their confidence in this challenging and technical project!

We’ll get back to you with more details on the scope as the project progresses, so stay tuned!