Integration of PLC programming and supervision and commissioning at an aluminium heat treatment plant in China

Industrial automation for aluminium heat treatment

Industrial automation plays a crucial role in optimising production processes, particularly in the aluminium heat treatment sector.

By integrating PLC programming systems, companies can not only improve the precision and efficiency of operations, but also guarantee the consistent quality of finished products.

The aluminium heat treatment plant benefits from reduced cycle times and production costs, while increasing process safety and reliability.

Our technical scope in industrial automation

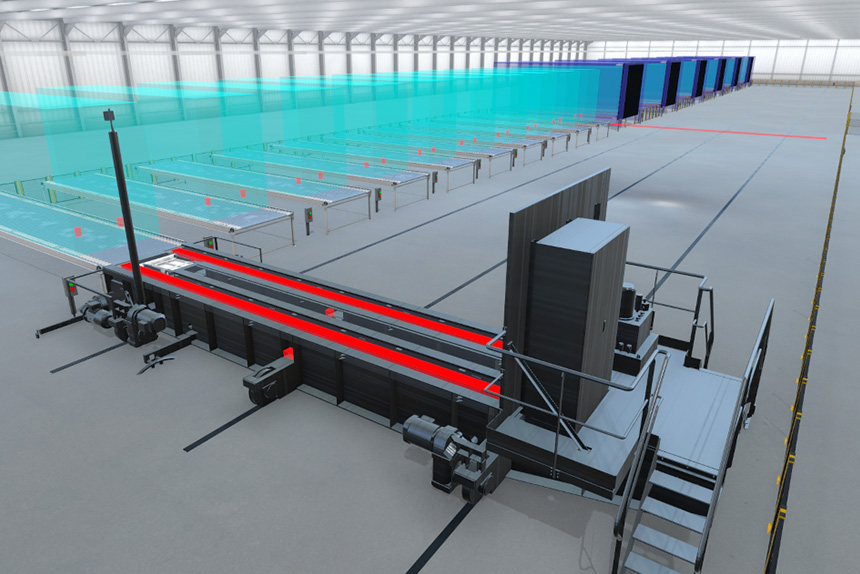

As part of the design of a second production unit for an aluminium heat treatment plant, we were asked to provide our expertise in PLC programming and supervision.

Our intervention covers the integration of these systems as well as their commissioning, ensuring the smooth and efficient deployment of the new installations.

The automation of the six furnaces and their loader is essential to guarantee optimum performance right from the start-up of this new production line.

Thanks to our Plug’n Test software solution, we were able to carry out virtual tests beforehand, reducing the risk of malfunctions during critical phases on site.

Our mission in China and our ability to carry out international commissioning

For this international project in China, our industrial automation specialists, Matthieu and Romain, are on site for an assignment lasting almost two months. Their on-site presence is essential for carrying out I/O and functional tests on the machines in real-life conditions, confirming the reliability of the installation before it is fully commissioned.

Our ability to operate anywhere in the world is testament to our expertise and commitment to delivering high quality industrial automation solutions. Whether in China or elsewhere, our international presence enables us to respond effectively to our customers’ needs, ensuring the success of their industrial projects.

Acknowledgements

We would like to thank our customer European Furnace Ropion for its trust in this challenging international industrial project.