Modification of a transitique system for a pneumatic plant in the USA – Focus on the worksite

Modification of a transitic system prior to the integration of a new device

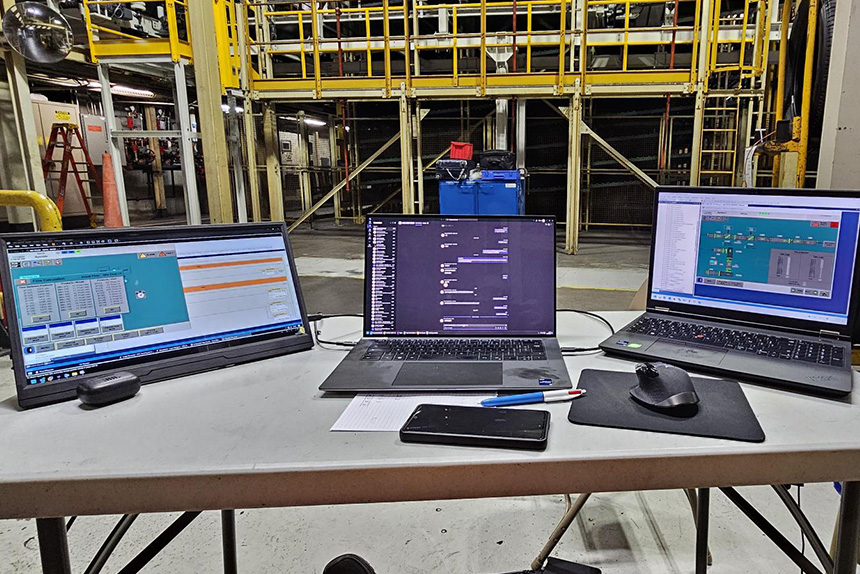

As part of the modification of an existing transitic system, prior to the integration of a new device, we visited a tire manufacturing plant in the United States. Industrial automation plays a crucial role in the optimal operation of transitic systems, ensuring the correct routing of materials and finished products throughout the manufacturing process. To ensure a smooth transition and successful integration, our experts carried out in-depth studies and prepared a precise and rigorous commissioning of the PLCs managing the various conveyors.

The challenges of transitic systems in tyre manufacturing plants

Transitic systems in tire manufacturing plants are complex and essential for maintaining efficient and continuous production. These systems comprise various conveyors that transport raw materials, intermediate components and finished products between the various stages of the tire manufacturing process. The aim is to minimise downtime and optimise productivity, while ensuring product safety and quality.

Our technical scope in industrial automation

After carrying out the studies, our industrial automation experts went on site to commission the newly added conveyors.

Our technical scope on this site included the design, installation and commissioning of the transitique systems. Our industrial automation specialists worked with the plant team to ensure that the conveyors integrated seamlessly with the existing system.

Our thoughts for our industrial automation experts

Acknowledgements

We thank our client Giordano&C S.p.A for its trust.