New automated material handling project for the tire logistics sector in the USA

We recently won a new contract in the logistics sector, and more specifically in the field of automated material handling, thanks to the renewed confidence of our long-standing customer Giordano C&S.p.A.

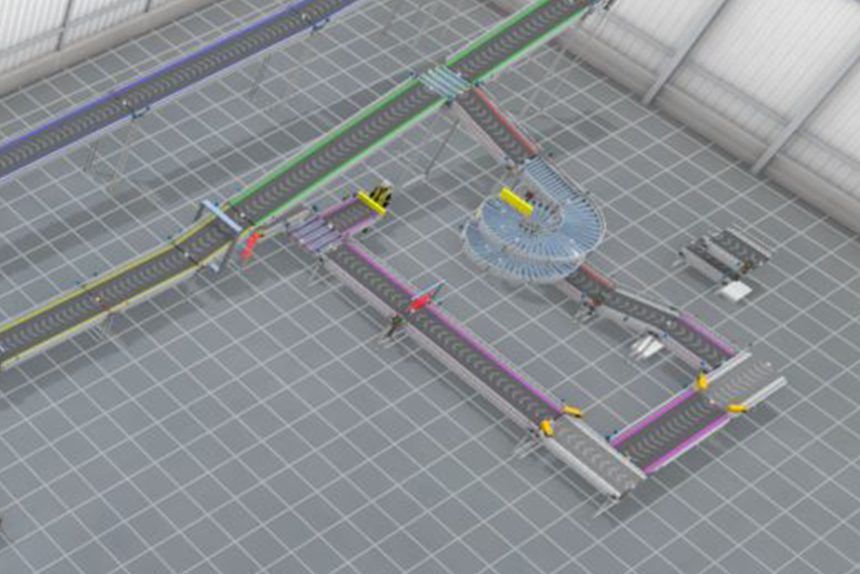

This major project involves the integration of a completely new automated material handling system at a tire manufacturing plant in the United States.

Our expertise in industrial automation will be applied to production logistics, with a particular focus on checking tires before they are palletized.

The automated material handling market applied to the tire sector

In the logistics sector, optimizing internal flows is crucial to improving productivity and reducing costs.

This is where material flow systems, or the automation of conveying and sorting systems, play a fundamental role, particularly in tire manufacturing plants.

Transitique systems help to streamline production stages, control quality and ensure precise product traceability.

In tire factories, palletizing tires is a critical stage.

It requires rigorous controls to ensure that each tire complies with quality and safety standards.

Thanks to our expertise in automation testing and handling systems, we are able to design solutions tailored to the needs of these production workshops.

Our presence in the tire plant automation market

Over the years, we have built up extensive experience in the field of automated handling systems for tire production.

Today, this know-how enables us to intervene effectively on complex projects in both Europe and the United States.

Our mastery of automated conveying technologies and our ability to provide tailor-made solutions make us a preferred partner for major players in the sector.

This new project with Giordano C&S.p.A strengthens our position in the tire plant material handling market. It illustrates our expertise in the design of automated systems dedicated to industrial logistics.

Details of our mission

Our intervention in this American plant will comprise several key stages:

- Automation studies: We will carry out the studies required for the complete automation of the new conveyor system.

- Simulated and functional tests: We will carry out simulated tests using our Plug’n Test software to validate the automation of the system before its implementation in the field, followed by functional tests to guarantee the correct operation of the process.

- Level 2 tests: These tests will validate that control and supervision are operating optimally.

- Commissioning: Finally, our team will visit the site to supervise the installation and ensure that the system operates correctly under real-life conditions.

Thanks to these different stages, we guarantee maximum optimization of production flows and perfect integration of the automation system into the plant environment.

Thanks to our customer

We would like to express our gratitude to Giordano C&S.p.A for their continued trust and loyalty.

This project testifies to our ability to meet the challenges of logistics and handling systems in complex industrial environments.