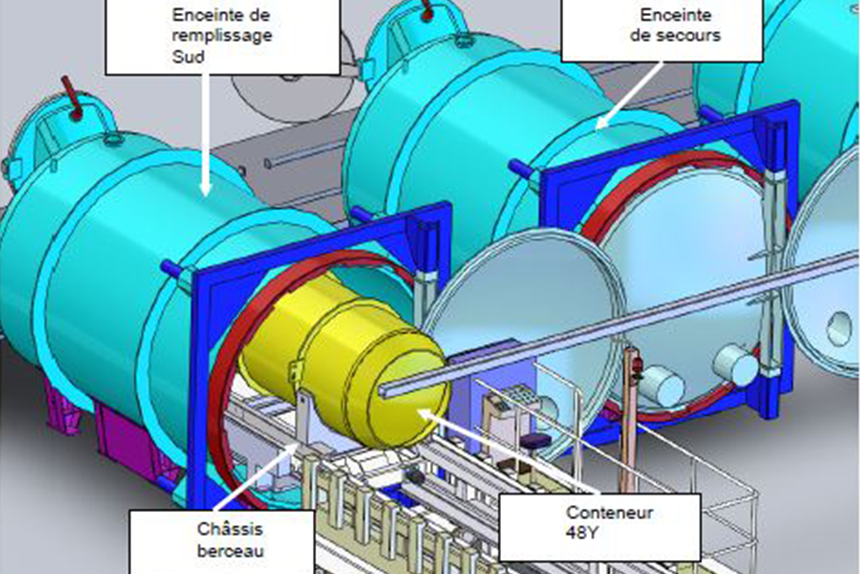

Our electrical automation engineers worked on the 48Y container filling process during cold trials at a uranium (UF6) conversion plant.

The scope of our intervention included a set of machine tests conducted during a two month service period:

- Electrical checks,

- Sensor function tests during sequences of filling 48Y containers with UF6

- Safety : emergency stop, gas detector, torquing, waterproofing,

- Local tests : power, input/output (automation architecture),

- Adjustment and calibration of the weighing of containers,

- Operator interfaces,

- Functional modes : automatic, manual, and semi-automatic,

- Communication with level 2 (in coordination with AREVA),

- Filling out testing sheets (Quality AREVA),

We thank our client for their confidence

The Key Elements

- Safety procedures

- Nuclear fuel conditioning

- Testing to specification

#IESAAutomation #Automation #Automatisme #ElectricitéIndustrielle #IndustrialElectricity #Nucléaire #NuclearIndustry #UF6 #48YContainerFilliing #Fluoridation #ColdTrials #Tests #SchneiderAdvantys #ConversionUranium #Comurhex