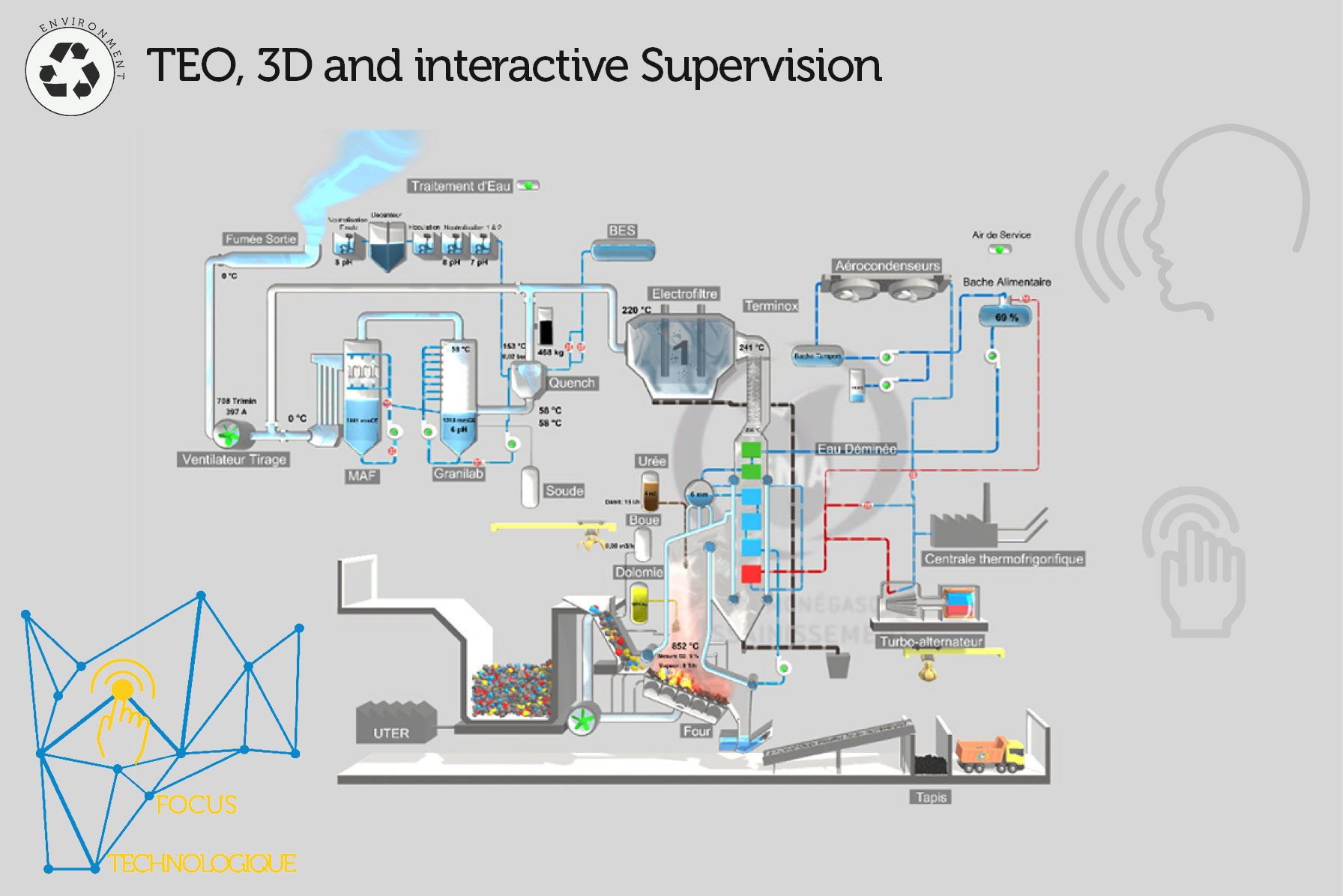

Technological focus – 3D and interactive supervision

Towards a new type of supervision

IESA has developped an innovative 3D and interactive tool to assist plant management : it is, tactile and voice-activated !

Thanks to its graphical interface, you can visualize your whole installation!

An easier visualization for visitors, a real time saving for technicians and an efficient management for executives!

How and why have we proposed this tool ?

The Monaco waste treatment plant, a historical client for IESA, is a player resolutely focused on innovation and cutting-edge technologies.

Attracted by the technical challenges, our team of experts in automation and 3D simulation were the driving force behind this dynamic and interactive tool. The mock-up was adopted, then the project was supported and encouraged throughout the process. This device was designed in partnership with CNIM, responsible for the renovation of the plant.

Our teams then created an application from the mock-up in close contact

The functionalities of the tool!

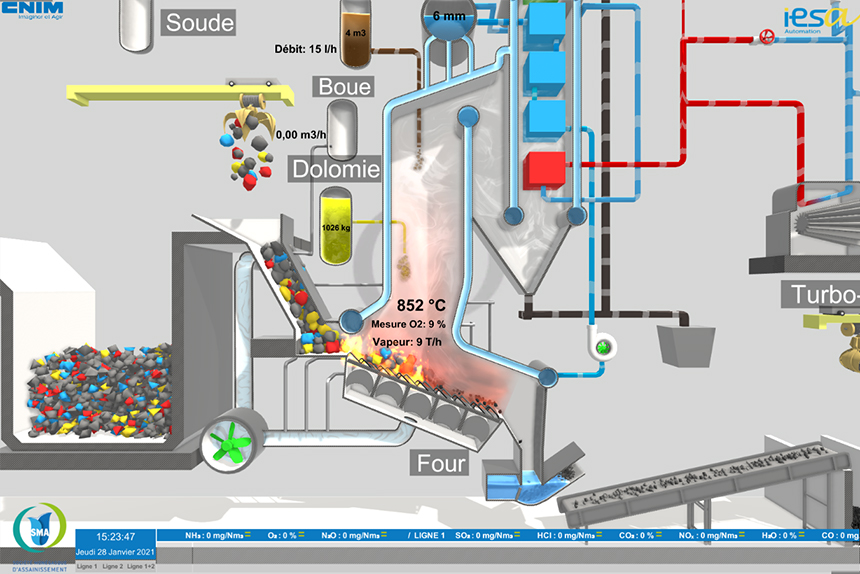

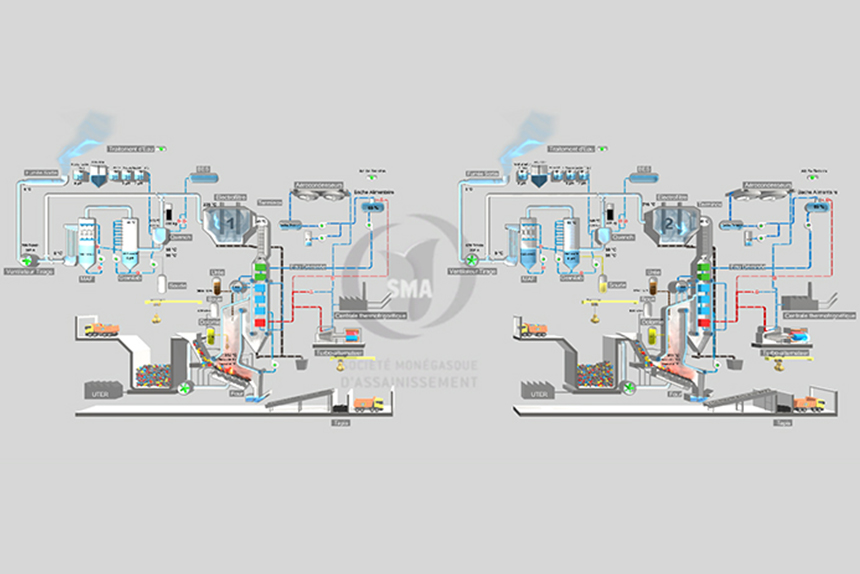

The waste-to-energy plant includes two boiler furnaces and two smoke treatment lines. The energy from combustion is recovered in two forms: electricity and steam.

The design, then the various upgrades of this installation have always enabled it to meet European standards in terms of respect for the environment, and in particular those relating to atmospheric emissions.

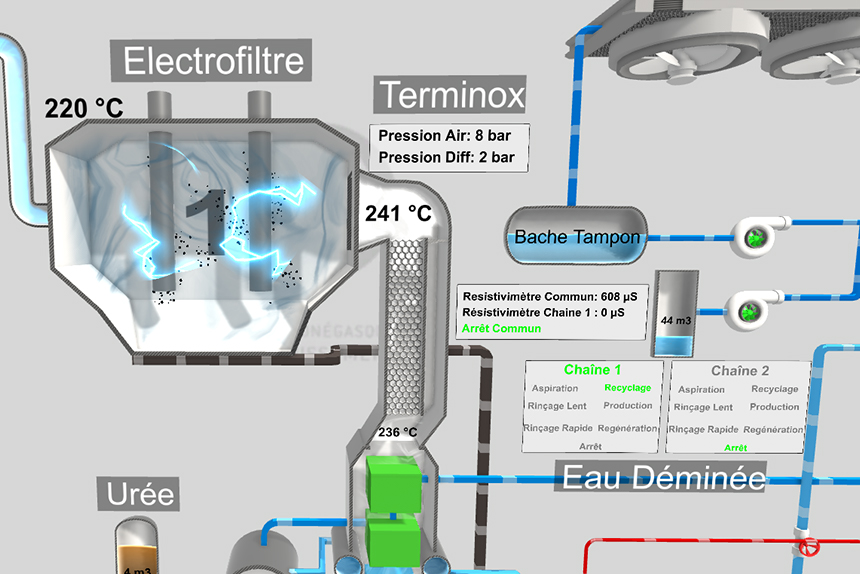

The 3D graphic display allows a clearer view of the installation and to visualize the indicators of the process: temperatures, fluids, levels of the different products… You can quickly identify, too, the operating status of the plant.

A scrolling banner give acces to the values of rejects and their trends for the sake of transparency. It also provides a follow-up of current alarms.

The tool also integrates a system for providing files relating to the information necessary for the good organization of the technical teams (planning, procedures, etc…).

All the data integrated in the application can be displayed either by voice or by touch.

Some screen shots of the tool

Boiler Line 1

The 2 smoke treatment lines

Zoom function

A 100% IESA achievement

In Automation : we carried out the development of the communication, as well as the exchange tables.

In 3D simulation : we developed the 3D, synoptic and voice command. We also created the tactile interface, and integrated the navigation functions. We relied on tools we already use before to design our 3D simulators, such as Unity 3D (Graphics Engine) or Blender (Computer Graphics).

A real challenge

Starting from an existing synoptic in order to integrate it in 3D, then to animate it, to make it more readable and interactive, was a real challenge. Our technical teams have successfully taken it up !

A unique design created by IESA integrating “TEO” (TErminal Operator, the name of this technology). This tool is used to quickly visualize the process equipment: to control it, you just have to ask the question directly to the voice assistant.

2 IESA supervisions implemented on touch and interactive screens were delivered and installed in the control room when it was renovated in early autumn 2020.